E-Torque has completely re-engineered the iconic Jaguar XK engine to make it powerful and reliable as never before

The cylinder head is the single greatest driver of power and torque.

We began in 2016 to design the first totally new cylinder head for the XK engine in 70 years that can add 100 horsepower or more to your XK Jaguar engine — and produce far more torque over a wider RPM range. For the first time, it made possible a twin spark plug ignition system, which had been proven effective for engines with hemispherical pistons, such as the Ferrari, Lamborghini, Maserati, Alpha Romeo, Cosworth and Aston Martin.

The E-Torque Cylinder Head has been specifically designed for the Jaguar connoisseur who desires modern performance and everyday drivability from his classic Jaguar without violating the authenticity of his classic car. All innovations are contained beneath the period appearance of the original head.

It was not long after dyno testing our prototype head, we discovered that virtually everything attached to it was restricting performance made possible by our design. We then set our sites to make improvements that eliminate these restrictions, which has led to the creation of three electronic fuel injection systems, several custom exhaust systems and an array of air filtration (pre-induction) systems.

We are now able to provide anything from a single spark replacement cylinder head to a Twin Spark, 4.7 litre stroker head, which has been recently dyno tested at over 400 hp. We have developed a product line that can provide bespoke opportunities to enhance any Jaguar to which they are fitted.

Although these parts are expensive compared to similar, mass produced items for other cars, for those who want a Jaguar of distinction, there are no inexpensive routes.

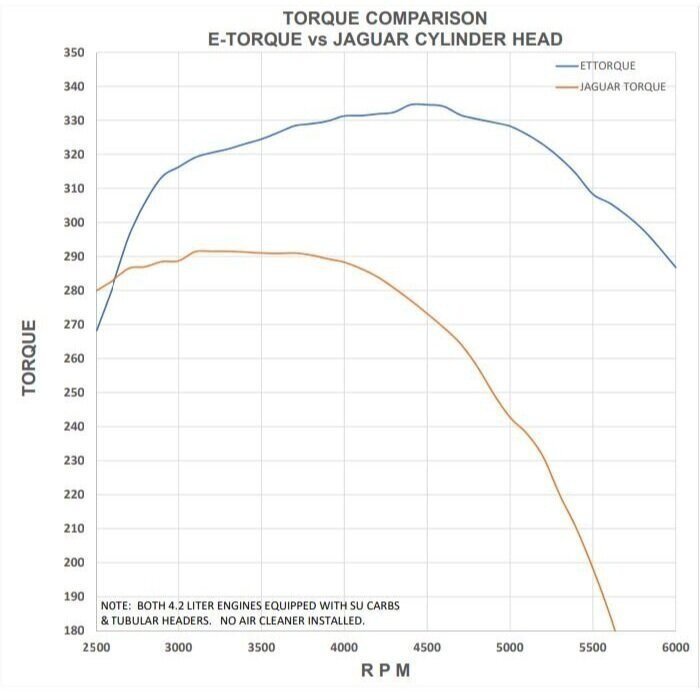

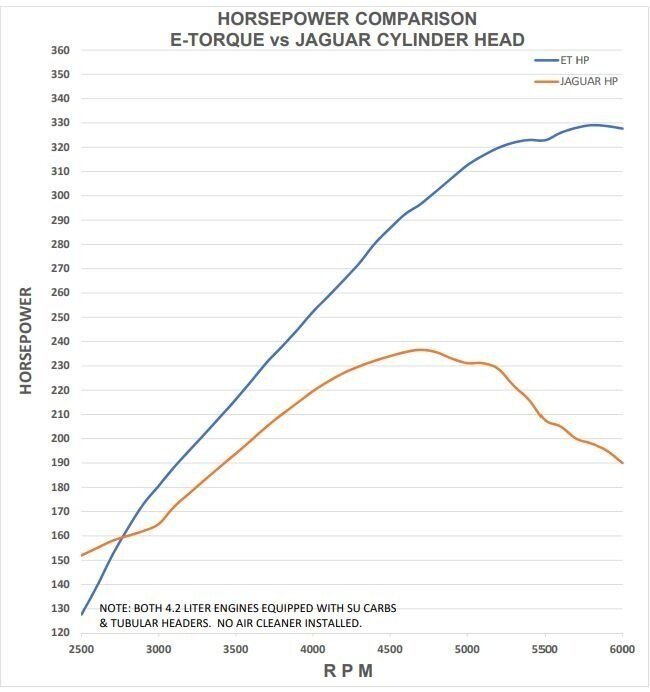

The line charts below show the results from our prototype Twin Spark cylinder head on a blueprinted, bone stock, 4.2 litre Jaguar engine

E-Torque Cylinder Head Choices

Pick Your Displacement

Jaguar 4.1 L

(3.8 L Stroked)

Jaguar 4.7 L

(4.2 L Stroked)

A WORD ABOUT STROKING

Back in the day when the XK engine was conceived, it was believed that connecting rods couldn’t be long enough. They were worried about the angularity of the rod at the start of the power stroke pushing more sideways than downward. Soon, a few guys in California created the American V8 with short rods and far more power. That theory about rod length was disproved. This is why the XK engine is begging to be “Stroked”. By making the offset on the crankshaft longer, it makes the rod ratio more ideal. A stroked XK engine (115mm offset) has a rod ratio of 1.71:1, which is pretty near perfect! This modification also adds torque and allows the engine to develop peak power at a lower RPM.

Twin Spark Ignition System

This system relies upon two six-post coil packs, which were developed for a modern Ford V6. These allow us to remove the most unreliable part of an ignition system - the Cap & Rotor - one that haunted the reliability of XK Jaguars until they discontinued them in 1987. Each coil pack is hidden from sight in the engine compartment.

This system is run by a small ECU that is capable of sensing engine load through a MAP sensor, and coolant temperature, which it uses to operate any electric fan you may use.

The system includes a custom wiring harness, which uses military specification wire to keep water intrusion from causing problems.

The custom made distributor is made from billet aluminum and has a ball bearing drive.

SU Styled EFI (E-type only)

We have developed a SU style EFI system. As with the cylinder head, it appears as a vintage assembly but is very modern on the inside. The SU HD8 carburetor has a two-inch throat. Our SU styled throttle bodies have 60mm bores. This allows for enhanced air flow to the engine.

The custom intake manifold has its fuel injectors hidden underneath and a fully thermally isolated water manifold to keep incoming air cool. These systems are sold with new-original SU float chambers to further protect the vintage appearance of the assembly.

This assembly has an optional pre-induction system, which replaces the Jaguar air filter canister with one that is far larger. It also replaces the fiberglass plenum with a tubular manifold that is lurking beneath a fiberglass cover to resemble the original parts. There is a 3.250” cold air tube that pipes air from the duct in the bonnet to the canister inlet so the engine doesn’t see hot air from behind the radiator. Since the E-Torque cylinder head will significantly raise the compression ratio, keeping the incoming air cooler is an important consideration. We will also offer a side draft air filter assembly later on.

The custom Twin Spark distributor is shown with a flat cap because it is electronic and uses coil packs to deliver spark to the cylinders. This also provides room for the large diameter Cold Air tube to pass by it. The throttle linkage connects to the original on the E-type keeping things looking stock.

Weber Style EFI (E-type Only)

The Weber style EFI is for those who are not so wedded to the SU appearance under the hood of their Jaguar. Weber conversions were common back in the 1960’s because they improved the mid-range torque so well. That difference in performance is not as pronounced in a fuel injected engine because the injectors do not rely upon vacuum to get fuel into the engine.

We developed a custom Weber styled intake manifold for this system with the injectors below as we did for the SU EFI system. It also has the water manifold separated from the air passages to keep the inlet temperatures down. Both manifolds have integrated Idle Air, Throttle Position, Inlet Air Temp and Map sensors installed.

As with the SU EFI, we have ported our larger air filter canister to the throttle body inlets using a trumpeted manifold. We have also developed a plenum style pre-induction system that would lend itself to high RPM performance where the manifold system is better for low and mid-range torque. We will be developing a side draft pre-induction system for those who don’t mind losing the original looking air filter canister. This will however lose some tuned length in the runners.

XK(120, 140 & 150) & XJ6 EFI SYSTEMS

We have recently developed a variation of the Weber EFI system to fit the XK cars and the XJ6. It is conceivable that this system will also fit the 3.8 series sedans and the Mk II cars.

This system is based upon the development of a thin throttle body, which is only one inch thick. The pre-induction manifold and plenum provide necessary tuned runner length to make the system feasible (see image below right) and able to adapt to the confines of these narrow engine compartments.

This unique EFI system has its own plate-style air filter element, which was custom made for it. The element is held on a tray that is attached to the bottom of the plenum using a series of spring clips. Incorporating the pre-induction system into the plenum is what provided the correct packaging that made this EFI system a reality for these classic cars that suffer from poor induction systems, unreliable starting and choking black smoke.

All of these cars will draw cool air from in front of the radiator, which is piped using a flexible tube to the inlet of the air filter chamber.

This system may not be feasible for a right hand drive XK car since the steering rod is so high under the induction system. A modern steering system with an intermediate shaft could however solve this problem.

Bottom End Parts & Stroker Kits

E-Torque stocks both standard stroke and stroker bottom end parts for your XK engine. These can be purchased as individual parts or in kit form.

Billet Steel crankshafts are much stronger than stock cast steel cranks, and when you dramatically increase power and torque, this is a significant difference. Steel cranks can raise the red line as much as 1,500 RPM (6500 recommended) which makes for much better HP numbers.

Lastly, E-Torque’s crankshafts will eliminate the chronic leaking rear seal that plagues cars with the original engine making the underside an oily mess.

Custom Cam Covers

We offer polished aluminum cam covers for those who want their Jaguar engine to look distinctive. The E-Torque cylinder head has seven cam bearings and our cam covers allow each pair to be used aesthetically and to provide better sealing with the head.

Each pair of cam covers comes with Cometic gaskets, and a new oil cap. Notice that our oil cap is located on the right back corner of the engine where Jaguar had it on the front-right side. This is because the first Jaguars that used the XK engine were XK120’s, which had a bonnet that opened from the front of the car. We moved the cap to the back left because E-types have a bonnet that opens from the back. We moved the cap to the right side of the car so oil would not spill on hot exhaust manifolds and the fill cap would be located away from traffic if you were on the shoulder of a road.

E-Torque Custom Exhaust Systems

The image to the upper left shows a pile of parts we used to find out what works best with each of our cylinder head models. The tall system standing upright is the original exhaust system with two individual silencers and resonators. That was compared to various combinations of parts selected from the ones shown. After two hundred pulls on the dyno, we finally broke the crankshaft in our test engine so we still have more testing to do. We did however manage to find an additional 50 lb/ft torque @ 2500 RPM before we quit.

The image to the lower left shows our exhaust configurator. It can be found by going to the header bar under “Products”. By selecting an engine displacement and other options, a visitor to our website can design an exhaust system that is exactly suited to his specific engine.

We stock full exhaust systems for the E-type and can order other for the XK cars and the XJ6 upon request. We offer both the separated four tip resonators as you would have on a Ferrari and the traditional style as well.